Lam Research Shipping Trends

Lam Research Corporation engineers, manufactures, and maintains semiconductor processing equipment used in the creation of integrated circuits.

Overview

Lam had a shipping process devoted to the shipment of developmental parts. When I started, there were tons of questions flying around. There was one omnipresent question hovering over them all; how long does it actually take to ship a part with this process?

Challenges

- There was a lot of data being generated: how parts were being shipped, how much they cost, where they were going, which manager approved the shipment, etc.

- There were questions the team knew they wanted answered, such as how long it took to ship, but other questions weren’t as easy to develop without the data on hand to look at.

- An interface had been built using Qlik Sense to try to answer some of these questions, but it incorrectly calculated the time causing a lack of trust.

Solutions

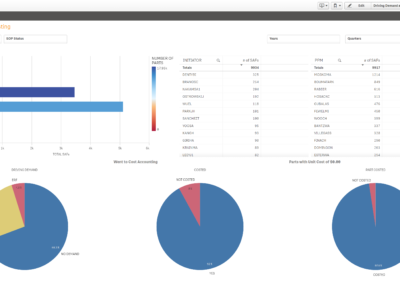

- Centralize all the data. There were lots of different dashboards, Excel sheets, and PowerPoints floating around. I consolidated everything into one place. This eliminated any issues with mismatching data due to different dates, different filters applied, etc.

- Create easy to read, dynamic charts with Qlik Sense.

- Identify key questions that needed to be answered and develop likely user paths through the data. Cater the dashboards to these experiences.

Results

- Once I had built the data analytics dashboard, we were able to uncover a $6,000,000 savings opportunity per year.

- We found that a big bottleneck was un-costed parts. Once we resolved this, our shipping time improved by 87%.

- By forcing parts to require a cost, we were able to reduce the one’s missing cost by 99%.

Identified Savings Potential Per Year

%

Improved Shipping Speed

%

Reduction in Parts Missing Costing

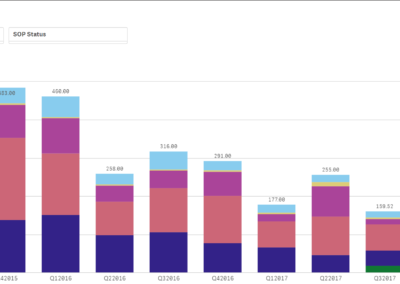

Processing Time

Once I was able to assemble the data, it became clear that processing time was way longer than expected. One of the main factors was the requirement for parts to be costed before shipping internationally. Parts were supposed to be costed before coming into the process, hence the hangup.

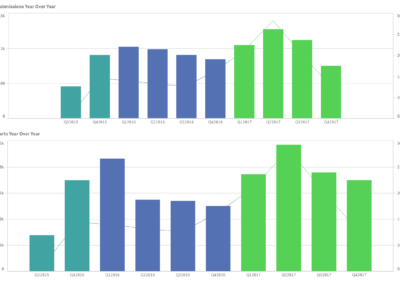

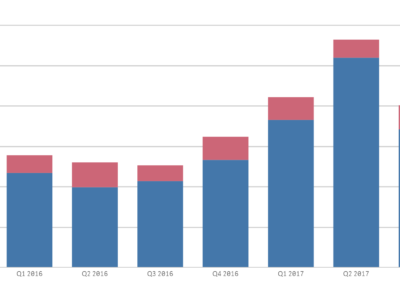

Parts Shipped Over Time

There was the assumption that we were always shipping more with this process, but there was no data backing up this claim. I put together a chart to see what the trends were.

1-4-2018 3-21-15 PM

Parts not being costed turned out to be one of the big hindrances to getting them through the process. I developed these charts to help identify if there were any trends with the missing costing.